Round Carbide/HSS

Grinding wheels

The demands for high performance on carbide & HSS round tool grinding requires unique design that match optimized bond Wear-Behavior and special abrasives Diamond and CBN grain.

A ONE INDUSTRIAL wheels have proven bond and grain systems effectiveness behavior, characterized by Lower power consumption and Higher Feed rates at low spindle loads, Leads to wide range of process-optimization.

Our bond system matrices extends grinding efficiency by shorter cycle times and long wheel service lives, guarantees consistency of grinding quality throughout the wheel life.

Typical Wheel Shapes

For Flute, Gash, Clearance edge and cylinder grinding operations

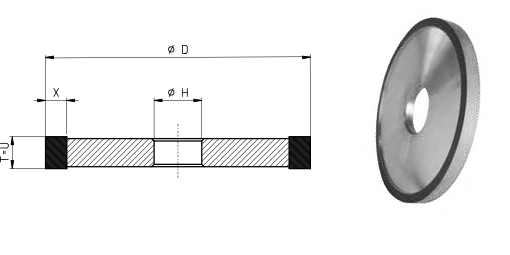

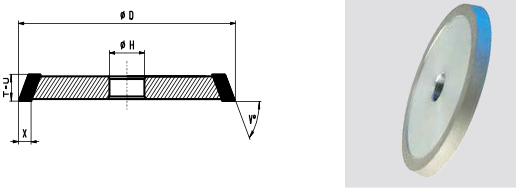

1A1

Variety of wheels diameter (D) from 2″ to 7-7/8″,

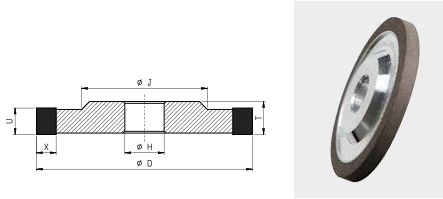

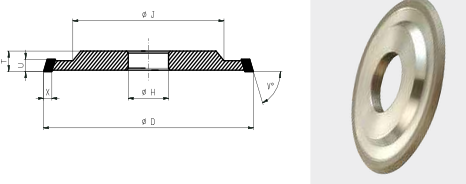

3A1

Variety of wheels diameter (D) from 2″ to 7-7/8″,

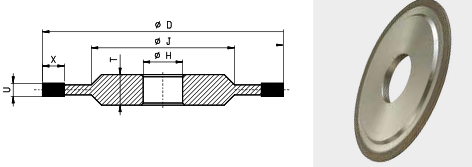

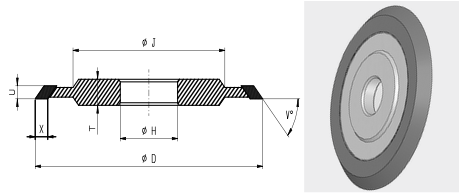

14A1

Variety of wheels diameter (D) from 2″ to 7-7/8″,

1V1

Variety of wheels diameter (D) from 2″ to 5″,

3V1

Variety of wheels diameter (D) from 2″ to 5″,

14V1

Variety of wheels diameter (D) from 2″ to 5″,

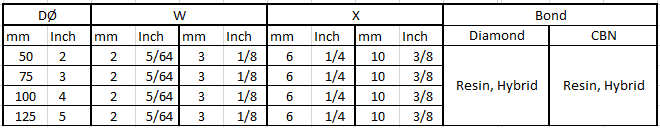

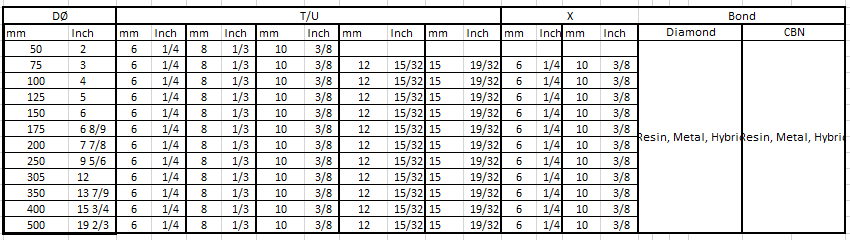

Typical Wheel Dimensions

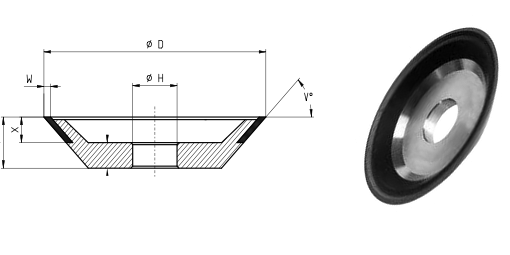

12V9/45*

Variety of wheels diameter (D) from 2″ to 5″,

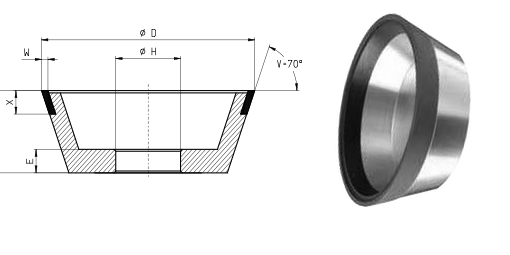

11V9/70*

Variety of wheels diameter (D) from 2″ to 5″,

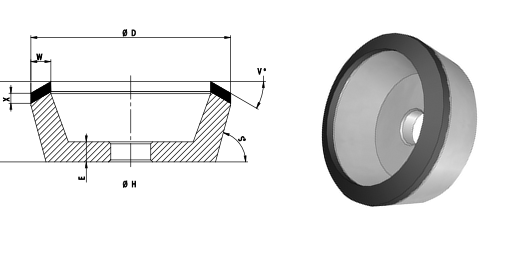

11V5/20*

Variety of wheels diameter (D) from 2″ to 5″,

Typical Wheel Dimensions